CTI Division

Phone: 330.644.3059

Fax: 330.644.8110

CTI Division

Address: 2740 Cory Ave

Akron, Ohio USA 44314

Email CTI Division

Sales@PolingGroup.com

Website

www.Comtime.com

The Poling Group is certified ISO 9001:2015 with design ( View Certificate )

The History of CTI - Commercial Timesharing, Inc.

CTI has always been forward-thinking - anticipating, designing, and implementing solutions whenever we identify new technology that will benefit our customers. Here are some notable examples:

- Adopted UNIX/LINUX to create real-time, robust, virus-resistant applications

- Created a UNIX/LINUX OS to run completely memory-based on a diskless industrialized PC that enabled our customers to set up workstations that could live on the factory floor

- Developed a transaction processing system to ensure chronological delivery of production data from the factory floor to an upper-level computer system in the event of network disruptions

- Designed PLCIO, the tool of choice for high-speed communications to a variety of PLCs from UNIX/LINUX applications

In 2000 CTI joined forces with Akron Special Machinery (ASM) to produce the first high-speed production uniformity testing machine capable of testing tires over 160 miles per hour and low-speed uniformity and dynamic balance results that correlated with existing machinery. This collaboration led to CTI being purchased by David Poling Sr. in 2001. Having purchased 5 companies, David Poling Sr. decided to unify the group of companies in an AKA, ‘the Poling Group.’ In 2022, the group of five companies official merged into one entity, the Poling Group

Today's Focus

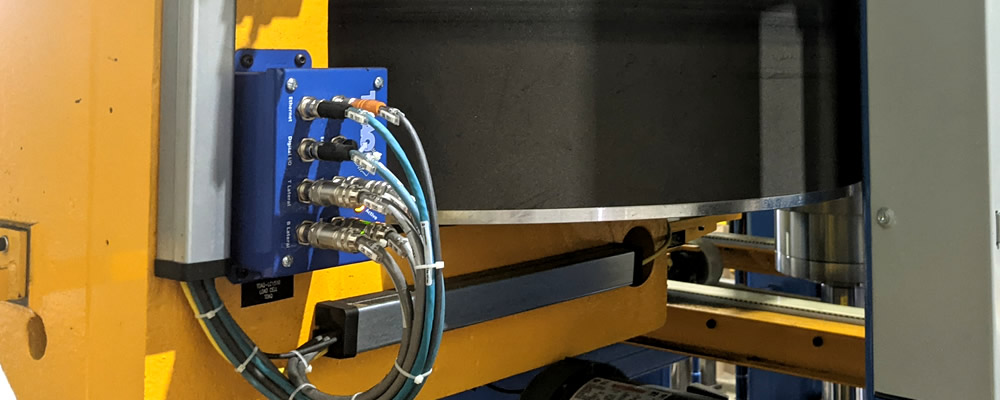

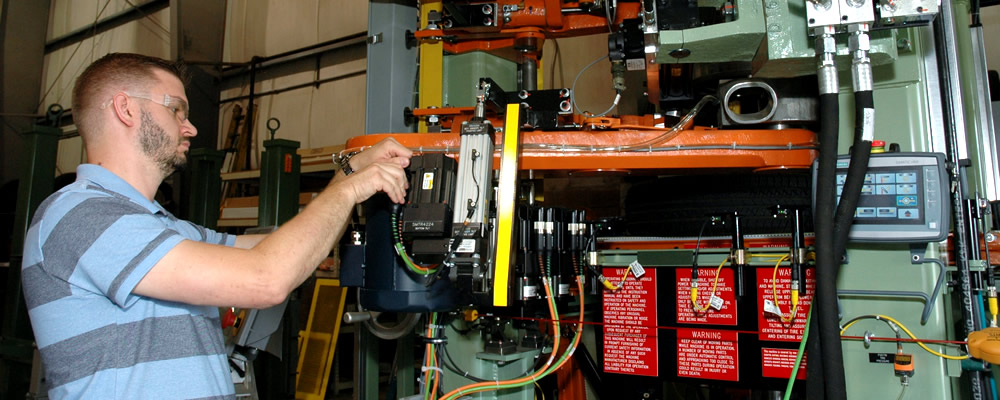

- TDAQ (Tire Data Acquisition) provides high-speed spindle-synchronized analog and digital data collection, including strain gauge amplification for the load cells. Because the TDAQ is small, modular, and ruggedized, it can be located on the machine near the sensors, and therefore only two cables (power and Ethernet) now efficiently replace the many signal wires leading back to the control panel of traditional tire test machines. TDAQ’s simplified wiring, combined with data acquisition closer to the source, produces stronger and cleaner analog signals to increase resolution substantially. With over 600 TDAQ’s in production since 2008 and only 15 failures, its reliability is unquestioned.

- WVC (Waveform Validation and Correction) software validates the collected force waveforms and applies any calculated corrections ensuring tires are tested more accurately and with greater repeatability within a faster measurement cycle.

- MECC (Machine Effect Characterization and Compensation) is a patented process for the characterization of mechanical deficiencies and then compensation to mitigate their effect on the test measurements. For example, an out-of-round loadwheel can still be used for testing while it’s waiting to be replaced because TTOC6 maps out the irregular shape of the loadwheel and removes unwanted effects from the test results.

- Remote, Real-Time Support is only a touch away in the Chat Panel. The Chat Panel blinks to alert machine personnel to incoming messages. Once expanded, this instant messaging application allows direct communication with Poling Group engineers to solve problems - without waiting for support to arrive on-site.

- Diagnostics and Plotting are powerful tools for quickly solving problems as they allow analog and digital signals, including PLC I/O, to be plotted simultaneously in real time.

- Optimization through shoulder grinders and a full-face tread (center) grinder can reduce a tire’s radial and lateral force and tread runout, including high-frequency bumps and dents. The TTOC6 has the broadest range of grinding algorithms in the tire industry, including combination grinds that can simultaneously optimize the force measurements with the shoulder grinders while optimizing tread runout with the center grinder, reducing overall optimization time.

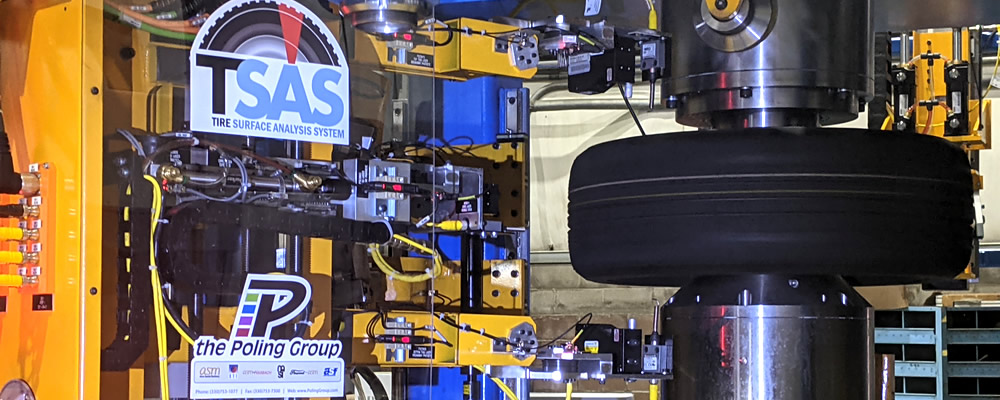

Another area of focus for the CTI Division is the continuous improvements to our laser geometry testing system, named TSAS (Tire Surface Analysis System). TSAS incorporates our patented Multi-Path Inspection (MPI) algorithm, complex mathematics, and 3D laser profile scanning (aka ‘sheet-of-light’ or ‘line laser’) to locate and accurately measure a tire’s geometry, including bulges, depressions, runout, wobble, and other customer-specific measurements. The TSAS software runs entirely within our TTOC6 or as a separate standalone application.

CTI Division also offers enterprise-level tire factory software solutions such as our FFH (Final Finish Host) and TFFIS (Tire Factory Floor Information System) products. FFH addresses Quality Assurance goals for all tires produced by the factory. FFH provides automated data collection of tire measurement results; centralized recipe management and automated delivery of those recipes to measurement machines; and comprehensive reporting on test counts, yield, machine utilization, and quality statistics, including drill down based on curing and build history. CTI provides remote support 24/7/365 for FFH. CTI will enhance FFH to meet a customer’s needs.

TFFIS is a real-time database system to facilitate efficiency in the tire manufacturing process. TFFIS facilitates automated material handling by providing routing decisions to PLCs that control of the flow of materials (i.e. tires, stock materials, etc.). TFFIS also facilitates the automated processing, by Final Finish equipment, of a diverse set of tire SKUs by providing a recipe assignment service based on a tire’s unique ID (i.e. barcode, RFID tag, etc.) to each piece of equipment. TFFIS collaborates with FFH to provide tire production history to FFH for reporting based on curing and build history. Other TFFIS features include in-process inventory, component traceability, and production accounting.

The CTI Division of the Poling Group is always focused on improving our current software and hardware products; and innovation utilizing data analytics, AI deep learning models, and robotics to engineer tomorrow’s solutions for smart manufacturing.

Five Divisions with One Goal ; We are committed to being a globally trusted source for tire-testing equipment & software, factory data management, rubber processing equipment, and engineering solutions.

Home Page | Contact | Website Terms & Conditions | Privacy Policy

©2024, the Poling Group. All Rights Reserved.