Firwood Division

Phone: 330.753.1077

Fax: 330.753.7308

Firwood Division

Address: 2740 Cory Ave

Akron, Ohio USA 44314

Email Firwood Division

Sales@PolingGroup.com

The Poling Group is certified ISO 9001:2015 with design (View Certificate)

The History of Firwood~ASM

Firwood Manufacturing Company was started by Merrill Ericson in 1940, on Firwood Street in Detroit, MI. Initially the company made small parts for the auto industry with Merrill working nights at Firwood and a day job in the tool room at Ford Motor Company. After much hard work and success, he left Ford to devote all his time to Firwood. The new company soon outgrew its building, and in 1948, moved to a new building on Kean Street in Dearborn, MI.

Merrill was a graduate of the Ford Trade School and used his education and sales skills to gain a reputation as a quality supplier of parts and assemblies to companies that included US Royal Tire Co. (Uniroyal). This association led to manufacturing the Post Cure Inflation machine for all the tire industry, as well as the development of White Sidewall Grinders, Bead Wrappers, Bias Cutters, Tread Skivers, and other production tire machines.

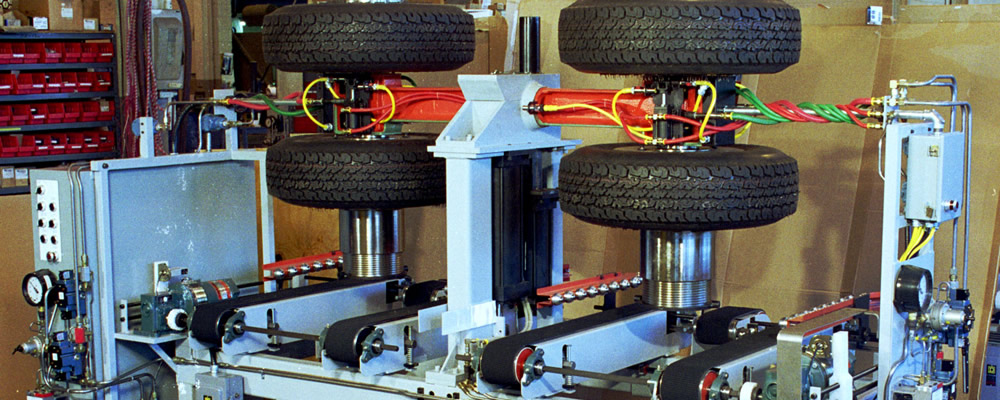

These were the booming years of auto growth - a perfect place for a company that was getting recognized for its tire equipment. In the 1970s, the factory floor was filled to capacity with Post Cure Inflators, a machine that allowed a tire to cool while inflated, which kept its internal integrity and set the heat memory of the man-made fibers in the tire. At the time, PCI’s were placed behind almost every tire press. (Like other products, many PCI's were retired; however, as of late, there is a need and demand for them once again.)

Also, during these years, Firwood gained a reputation for building White Sidewall Grinders. Firwood's Grinders were unique due to their sturdy frames and locking chucks which had a 100PSI specification. When checked in 2009, the first one ever made was still running full- time.

The next couple of decades were influenced by Steve Ericson, Merrill's youngest son. Steve, a design engineer, developed the automotive and special machinery side of Firwood and continued to upgrade the tire equipment for which the company was known. During this period, Firwood built equipment for GM, Ford, ITT, Williams International, American Hoffmann, and Hines Balancing. Firwood also designed and built heat treat, injection molding, and eddy current machines.

Today's Focus

- The company now provides White Sidewall Painters.

- The Sidewall Grinder has been upgraded, so it now has a measured centering device, while handling a tire up to 42" in diameter and has an optional servo control depth of grind.

- Firwood~ASM has developed an automatic retrofit package for its older Grinders and Post Cure Inflators.

Five Divisions with One Goal ; We are committed to being a globally trusted source for tire-testing equipment & software, factory data management, rubber processing equipment, and engineering solutions.

Home Page | Contact | Website Terms & Conditions | Privacy Policy

©2024, the Poling Group. All Rights Reserved.