Our 3 tier approach maximizes your investment by incrementally improving your equipment. And we can tailor any tier to meet your specific needs.

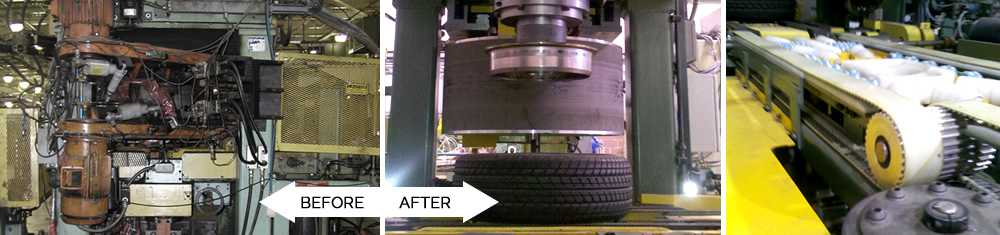

The Poling Group can fully remanufacture any Tire Uniformity testing machine, even if we didn't originally make it. This includes : D70, D70-LTX, D90, FD90, M91, X75, X100, X150, CX111, MCX75. Don't see your machine on the list? Use the form at the bottom of the page to ask us about it.

TIER

Replace your obsolete computer and data acquisition system with our TTOC6 computer and TDAQ data acquisition system - and keep your machine operational. This alone will greatly increase testing accuracy and repeatability, and does not require Tier 2 or Tier 3 upgrades.

Latest Control Technology with TTOC6

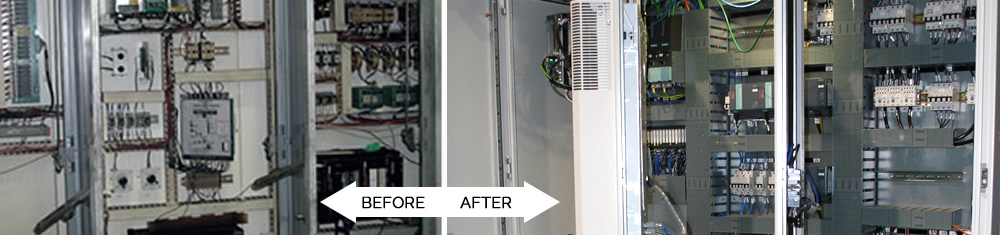

TIER Electrical Panel Upgrade

Electrical Panel Upgrade

Improve testing machine accuracy, uptime and maintainability, with an Electrical Panel Upgrade. Electrical Panel Upgrades require a previous Tier1 upgrade.

- Comes standard with Waveform Validation and Correction (WVC) software,an entirely new and proprietary way of collecting, evaluating and processing tire uniformity measurement information.

- Open architecture computer system for integrating barcode readers, marking systems, sorters, etc.

- Enterprise access and remote support

- Supervisory server/computer integration

- Centralize recipe management

- Product traceability and intelligent material handling

- Improved measurement accuracy using the TDAQ (Tire Data Acquisition) Module

- Better noise immunity

- Simplified maintenance with fewer electronic components and less points of failure

TIER

Improve testing machine accuracy, uptime and maintainability, with an Electrical Panel Upgrade. Electrical Panel Upgrades require a previous Tier1 upgrade.

- New electrical panels designed to fit existing footprint

- Choice of PLC with distributed I/O, servo automation & drive controls

- Diagnostics integrated with advanced help system

- Latest safety equipment

- Field upgraded with on-site supervisory installation support

- Automated recipe selection for mixed mode (lot size 1) production

The Poling Group offers more than 30 different machine & tooling options and upgrades. Remanufacturing requires previous Tier1 and Tier2 upgrades.

- Add new testing capabilities (like geometry or visual inspection)

- Improve machine performance with new hydraulic and air systems

- Enable production tracking such as barcode and marking systems

- Increase machine flexibility such as the range of tires tested at a single machine

- And many more!

The Poling Group has extensive experience helping our customers . .

- Remanufacture and upgrade machines onsite because they couldn’t be moved

- Develop a phased approach for remanufacturing to meet improved technology, product transition, or budgetary demands

- Standardize machines from different suppliers, for example:

• enforce a common (preferred) PLC

• integrate an existing supervisory computer

• introduce a new data acquisition system

• unify machines to reduce spare parts headaches