75 Years of Calendering Experience

Since 1946, the ASF Division has been designing, engineering and manufacturing rubber processing equipment and machinery. We are known for our extremely durable, custom-made calendering drums and line equipment.

Since 1946, the ASF Division has been designing, engineering and manufacturing rubber processing equipment and machinery. We are known for our extremely durable, custom-made calendering drums and line equipment.

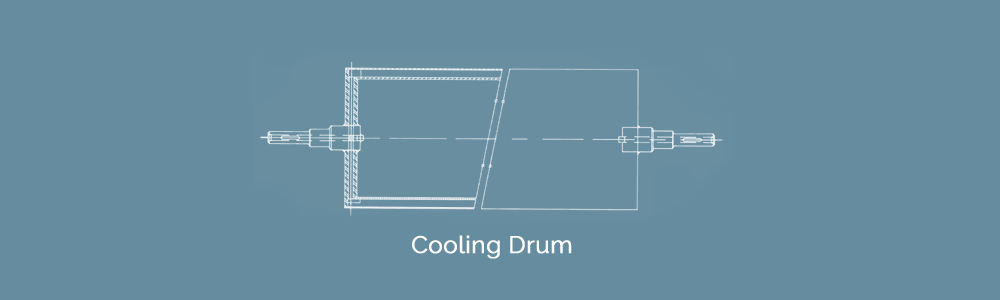

Standard Features

- Outside diameter precision machined to surface finish of 32 micro inches or better

- 0.005 maximum T.I.R. taken four places along drum face

- 0.005 maximum concentricity between drum face and bearing journals

- Statically balanced

- Drums individually boxed for shipment

- Standard construction, 23" diameter with other dimensions available

- Drum face lengths up to 128"

- Drum journals provided with pipe tap (both ends) for customer's rotary union

- Drum end painted to customer specification

Cooling Drum Stand

- Horizontal or vertical stands

- Driven or idler drums

- Complete with manifolds and required piping

- 304 stainless steel

- Carbon steel Teflon coated

- Carbon steel chrome plated 0.002 to 0.003 thickness (with or without matte finish)

- Carbon steel