The Poling Group's new Tire Geometry Testing Verification Wheel provides the quickest way possible to verify your LRO/RRO geometry testing lasers. The verification wheel chucks directly on your testing machine's current rims (up to 19") and therefore requires no machine requalifying after verification.

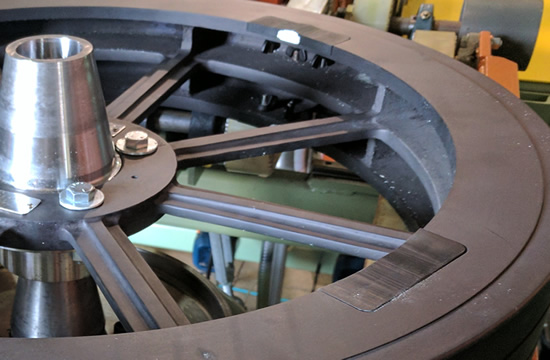

The Poling Group's new Tire Geometry Testing Verification Wheel provides the quickest way possible to verify your LRO/RRO geometry testing lasers. The verification wheel chucks directly on your testing machine's current rims (up to 19") and therefore requires no machine requalifying after verification.Lateral Runout (LRO) : Both sidewall faces consist of four bulge/depression plates of varying heights. A ring on the outer 1" has a height variant of .15" for precision verification.

Radial Runout (RRO) : Three bands on the 'tread' side of the wheel each have a different height variant to verify RRO laser measurements.

- Non-inflatable wheel provides precise height variants for geometry laser verification

- Measures LRO, RRO, Phase Adjusted Lateral (Wobble) and Bulge/Depression

- Can be chucked on machine rims up to 19"

- Resume testing after verification with no need to requalify machine

- Bulge/depression inserts can be custom made to customer requirements, with typical height variants of 0.020" to 0.100"

- Verification wheel is fully supported by TSAS Software

- ISO 17025 Certified by external source at the request of Customers. ISO Certificate provided GVW