Our Tire Factory Floor Information System (TFFIS) has enabled tire plants to move data from machines to the plant data center since 1997.

Smart Routing

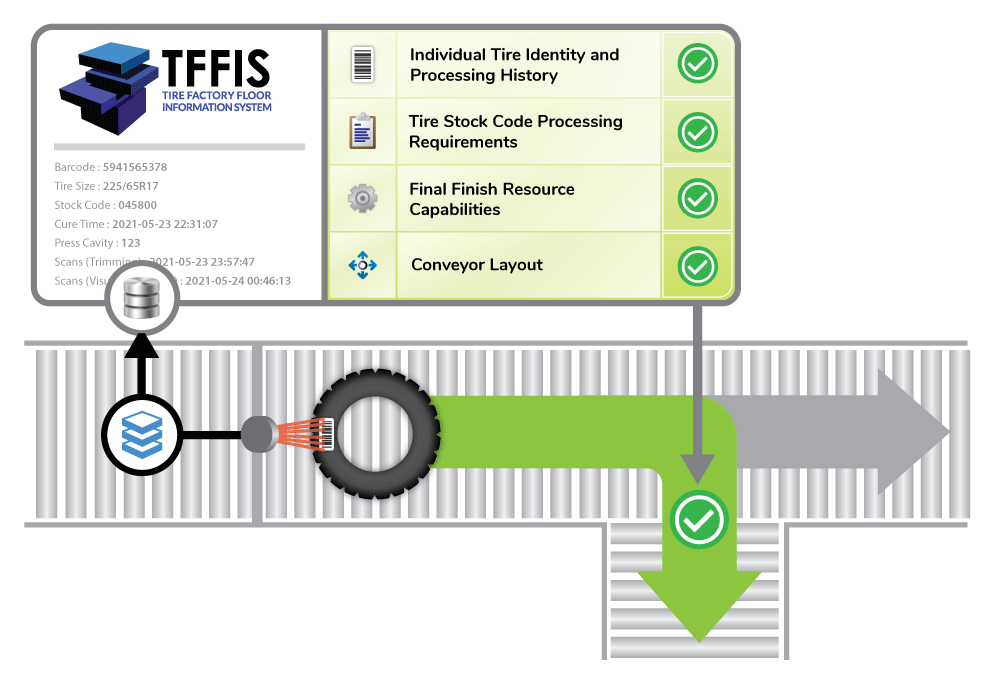

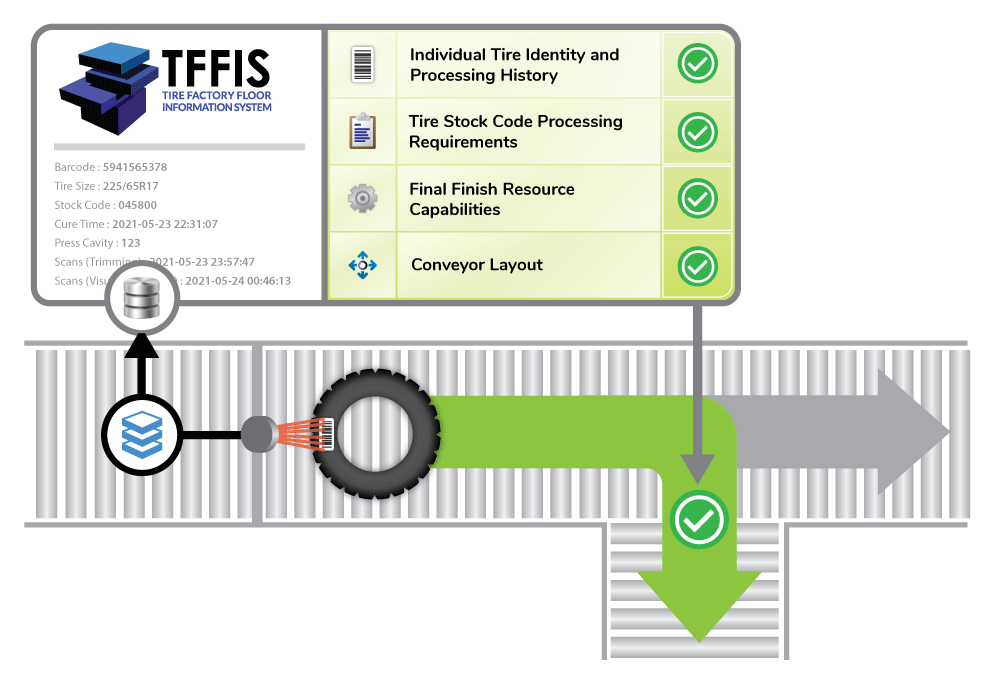

TFFIS has the capability of directing automated tire flow through final finish conveyors.

A PLC is well suited to make “ground level” decisions required to maintain sufficient spacing between tires, move tires from one conveyor segment to another, merge tires from converging conveyor segments, and track tires from a barcode scanner to a divert point.

TFFIS collaborates with the PLC. TFFIS provides the “big picture” decisions required to get the tire to its next procedure. It does this intelligently by combining information about the processing requirements for your stock codes, the individual tire’s identity and processing history, the capability and current tooling of your tire processing equipment, and the landscape layout of your final finish factory floor to decide the optimal path for the tire at each conveyor divert point. TFFIS communicates directly with the PLC to provide this decision for each tire at each barcode scanner.

TFFIS provides tire barcode identification services to tire measurement machines, primarily the name of the measurement recipe required to measure the tire.

TFFIS has the capability of directing automated tire flow through final finish conveyors.

A PLC is well suited to make “ground level” decisions required to maintain sufficient spacing between tires, move tires from one conveyor segment to another, merge tires from converging conveyor segments, and track tires from a barcode scanner to a divert point.

TFFIS collaborates with the PLC. TFFIS provides the “big picture” decisions required to get the tire to its next procedure. It does this intelligently by combining information about the processing requirements for your stock codes, the individual tire’s identity and processing history, the capability and current tooling of your tire processing equipment, and the landscape layout of your final finish factory floor to decide the optimal path for the tire at each conveyor divert point. TFFIS communicates directly with the PLC to provide this decision for each tire at each barcode scanner.

TFFIS provides tire barcode identification services to tire measurement machines, primarily the name of the measurement recipe required to measure the tire.

Reject Evaluation

- Efficient tire servicing with easy-to-read process history

- Replace damaged barcodes

- Discard unacceptable tires

Inspection

- Customizable, straight-forward HMI

- Effortlessly record visual inspection data

- Review upstream tire production history

The Power of TFFIS is in its flexibility

The Power of TFFIS is Always at your Fingertips

TFFIS delivers accurate production accounting

TFFIS Generated Reports

TFFIS delivers accurate production history

The Tire Production History report displays all production history of the tire, including if it was processed at an inspection station. The report also shows the next process for the tire in the final finish area.

TFFIS delivers extensive quality assurance

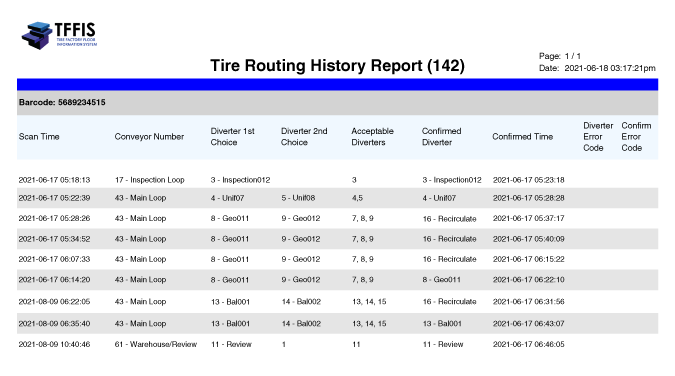

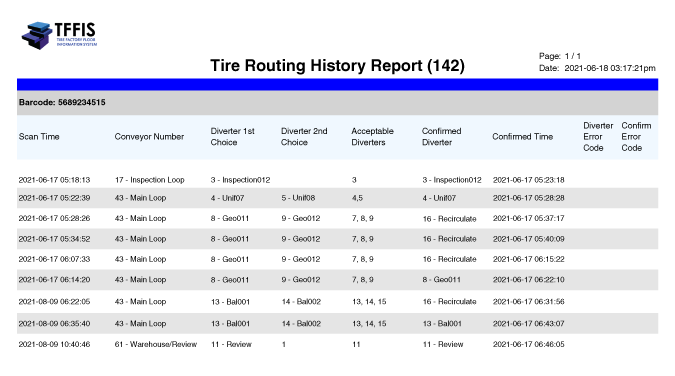

The Tire Routing History output is an extensive report of the tire's route throughout the conveyor system after leaving the hot inspection area on its way to the warehouse.

- TFFIS is customized to meet your specific needs, whether that is inventory management, product routing, component traceability, or a combination of all

- TFFIS comes with 24/7 remote support, typically from the very people that designed and implemented the software

- TFFIS is user-friendly – we work with the plant to make sure the UI is coherent and understandable to all plant and management staff

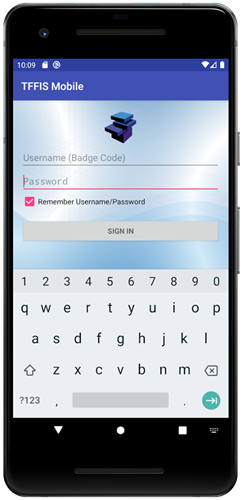

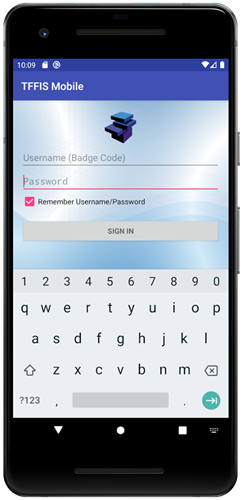

The Power of TFFIS is Always at your Fingertips

- Our Android TFFIS App allows plant users to scan a tire's barcode and receive all logged information about that tire. Anywhere in the factory, right to your phone

- Access plant and processing information while away from your desk

TFFIS delivers accurate production accounting

- TFFIS can be accessed anywhere in the plant and uses point-of-production and mobile workstation access points to provide activity and inventory tracking based on tire barcode

- Reports deliver accurate reporting of production against designed objectives

TFFIS Generated Reports

TFFIS delivers accurate production history

The Tire Production History report displays all production history of the tire, including if it was processed at an inspection station. The report also shows the next process for the tire in the final finish area.

TFFIS delivers extensive quality assurance

The Tire Routing History output is an extensive report of the tire's route throughout the conveyor system after leaving the hot inspection area on its way to the warehouse.