The TTOC6 Controller for Laboratory Tire Testing Has Arrived!

The TTOC6 Controller for Laboratory Tire Testing Has Arrived!For over 25 years, the industry’s most trusted and widely used controller for final finish tire testing is now available for Laboratory Tire Testing Machines. Built on advanced software that powers hundreds of Uniformity and Geometry testers worldwide, the CTI Division has redesigned the TTOC6 to deliver precise, reliable measurements for laboratory tire testing applications.

- New streamlined software, eliminating costly third-party applications

- Intuitive touchscreen graphical user interface

- Reliable Linux based software, easily accessible via web browser

- Machine Visualization window, with remote, real-time support

- Fewer electronic components, fewer points of failure, with better reliability

- Web-based recipe editor, message logs, servo setups and machine configuration

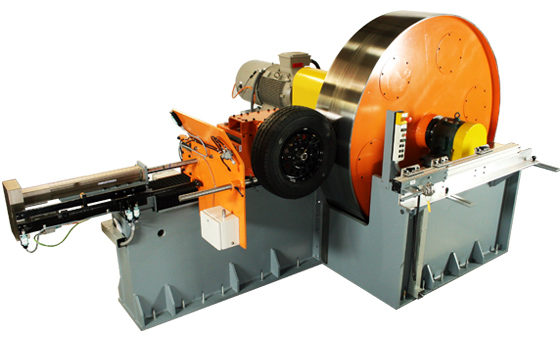

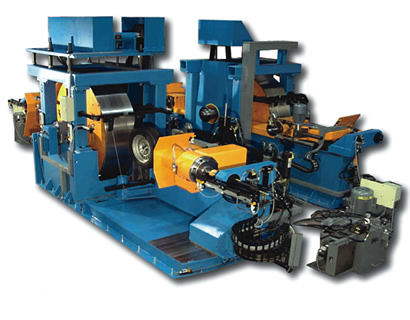

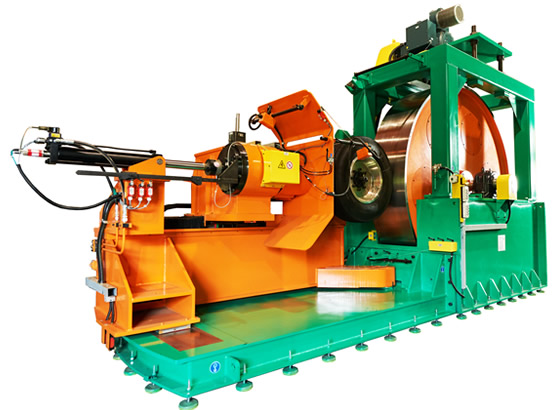

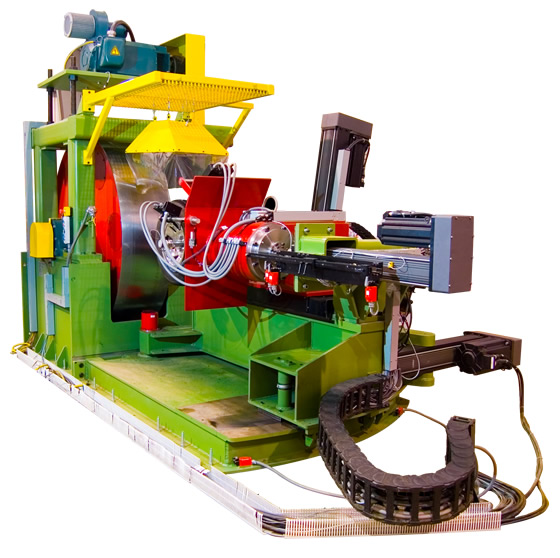

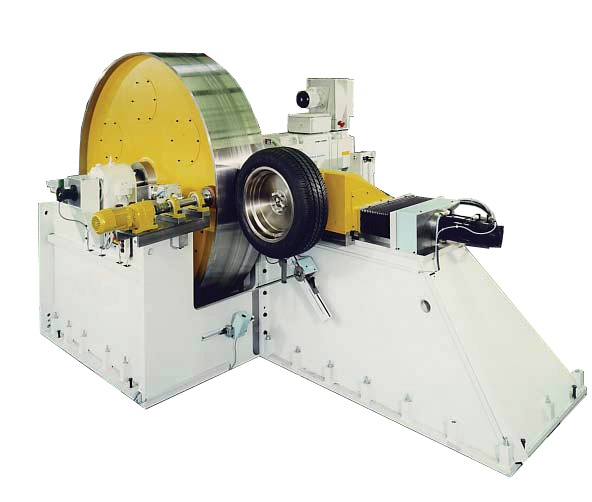

- Available on ALL new Hasbach Division laboratory tire testers, or as an upgrade to previous and third-party models

- Ask Us About Measuring Tire Growth

All laboratory testers have optional 24/7/365 remote support, provided by the team of engineers who develop, support, install, and commission them.

Five Divisions with One Goal ; We are committed to being a globally trusted source for tire-testing equipment & software, factory data management, rubber processing equipment, and engineering solutions.

Home Page | Contact | Website Terms & Conditions | Privacy Policy

©2026, the Poling Group. All Rights Reserved.