This patented concept for characterization of mechanical deficiencies and then compensation to mitigate the effect they have on the measurement is a huge step forward in advanced tire uniformity measurement methods. In addition to enhanced measurement results for high spring rate tires and even properly operating machines, the MECC process can provide a long lasting stop gap measure to achieve qualifying measurement results for a mechanically deficient machine PRIOR to repair or overhaul.

A common Quality Assurance (QA) practice in many tire factories is to run a "check" tire on each machine at least once a day. This process takes only a few minutes of production time and is used to determine proper correlation (magnitudes) for all measurements as well as providing an indicator of measurement repeatability. When the values of the "check" tire determine that the machine correlation or measurement repeatability have fallen outside a corporate QA specified tolerance, the machine must be repaired in some way to cause better measurement.

With MECC, it is now possible to run the characterization routine and, in many cases, the result is a set of compensation values that can be used to enhance the measurement values allowing the machine to correlate and repeat properly. The MECC process is a very nice alternative that allows the machine to stay in production while the machine is SCHEDULED for a time when mechanical repairs can be accomplished.

The MECC measurement method complements other recent Poling Group innovations like the new WVC measurement process and TAIR and Inflation Optimizaton software (TIO). Now included with all new Poling Group uniformity testing machines, MECC is also available with a TTOC6 controller upgrade on older machines.

A common Quality Assurance (QA) practice in many tire factories is to run a "check" tire on each machine at least once a day. This process takes only a few minutes of production time and is used to determine proper correlation (magnitudes) for all measurements as well as providing an indicator of measurement repeatability. When the values of the "check" tire determine that the machine correlation or measurement repeatability have fallen outside a corporate QA specified tolerance, the machine must be repaired in some way to cause better measurement.

With MECC, it is now possible to run the characterization routine and, in many cases, the result is a set of compensation values that can be used to enhance the measurement values allowing the machine to correlate and repeat properly. The MECC process is a very nice alternative that allows the machine to stay in production while the machine is SCHEDULED for a time when mechanical repairs can be accomplished.

The MECC measurement method complements other recent Poling Group innovations like the new WVC measurement process and TAIR and Inflation Optimizaton software (TIO). Now included with all new Poling Group uniformity testing machines, MECC is also available with a TTOC6 controller upgrade on older machines.

What 'Machine Effect' is, and how that information can be used

What 'Machine Effect' is, and how that information can be usedConsider the effect a loadwheel or rim/spindle combination that is no longer within specification (not totally round) has on uniformity measurements. That out-of-roundness will cause an effect in any uniformity measurement that has nothing to do with the tire's true uniformity. It will increase the TRUE radial force uniformity values or decrease them based on what portion of the loadwheel was in contact with the tire during measurement. That is the definition of a machine effect, in this case, loadwheel out-of-roundness.

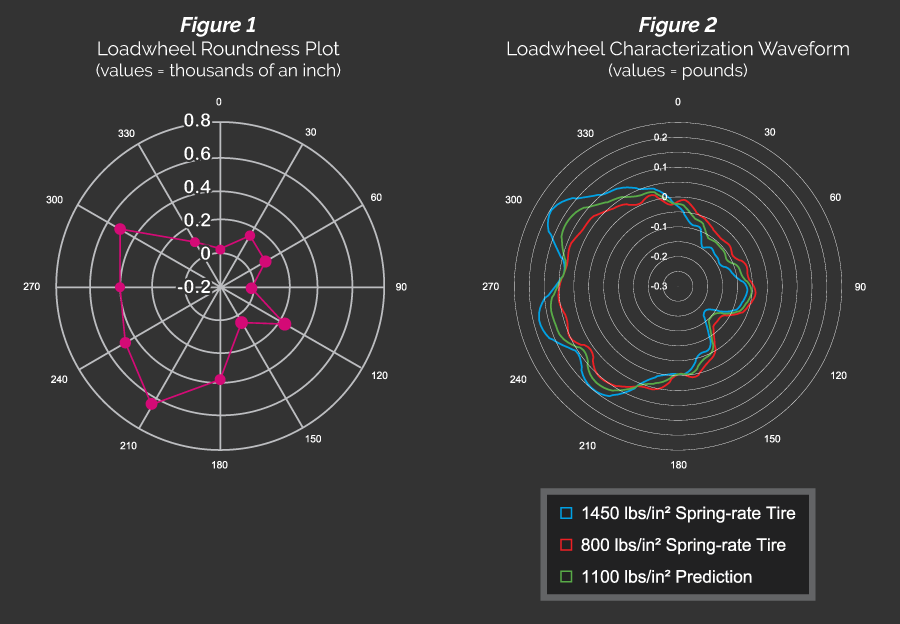

If the out-of-roundness looked like the loadwheel shown in figure 1 it would have an out-of-roundness of 0.0006 inches. While that is close to being an acceptable runout reading, it would still cause a problem with the radial measurement in a uniformity test.

So the question becomes, how big of a problem would that be? The answer is that it would be in proportion to the out-of-roundness of the part of the loadwheel that was involved in the uniformity measurement. The spring rate on an average 16 inch rim diameter tire is about 1000 LBS per inch of compression. So if the loadwheel with an out-of-roundness of 0.0006 inches was used to measure that tire, it could cause a measurement variance of up to 0.6 LBS. That amount of variance would not be considered good measurement repeatability.

How can the loadwheel out of roundness be characterized (calculated) and then how can that information be used to create a compensation process?

The standard loadwheel on a PCR/LTR uniformity machine is 33.6 inches in diameter and has a circumference of about 105 inches. A 225/70 R16 tire has a diameter of 28.4 inches and a circumference of about 89 inches. So a one-revolution test of the tire will use 89/105 of the loadwheel circumference. In our patent pending process of characterization and compensation, if a single tire is tested multiple times such that its waveforms are distributed evenly around the circumference of the loadwheel and averaged, the tire values will be lost and the loadwheel influence will emerge as a waveform which shows the effect of the loadwheel. In figure 2 we can see a force diagram that shows how the out-of-roundness of the loadwheel shown in figure 1 creates unwanted effects in the measurement of a tire.

Figure 2 is in fact, a plot of the waveform showing the EFFECT of the loadwheel out-of-roundness. Looking at that plot you can see that if the part of the loadwheel at about 20 degrees to 130 degrees was used to test the tire, it could remove as much as 0.15 LBS of force. And if the part of the loadwheel at about 210 to 310 degrees were used to test the tire, it could add about 0.2 LBS. Then it would follow that a compensation waveform could be developed from the characterization waveform such that the total of both waveforms would result in a sum of ZERO.

And finally, note how the standard measurement for loadwheel out-of-roundness done by all tire uniformity machine maintenance people is shown in figure 1. Can you see how it bears a striking resemblance in SHAPE to the force characterization shown in figure 2? That would be expected as loadwheel out-of-roundness is a large contributor to a machine’s measurement variance.

Until now, little could be done for a loadwheel that had reached an unacceptable level of out-of-roundness except to have it removed and refurbished.

Now with Machine Effect Characterization and Compensation (MECC), the characterization routine can be run and in just a few minutes a characterization waveform similar to the one shown in figure 2 can be developed and from that a compensation waveform. With MECC, a uniformity machine with a loadwheel in less than ideal condition can continue operating and reliably testing tires.

We’ve just explained how MECC compensates for deficiencies with the loadwheel, but the great news is that we have a MECC process for rims and spindle adapters also!