SMARTER

Advances like WVC, MECC, TAir, and 30+ other patented ideas make our machines the most accurate in the industry.

FASTER

Test thousands and thousands of tires per day with Poling Group's MCX75 and Final Finish Host, providing 1-direction tire testing assistance.

STRONGER

Recent advances in Poling Group technology allow our machines to test millions of tires before major wear parts need attention.

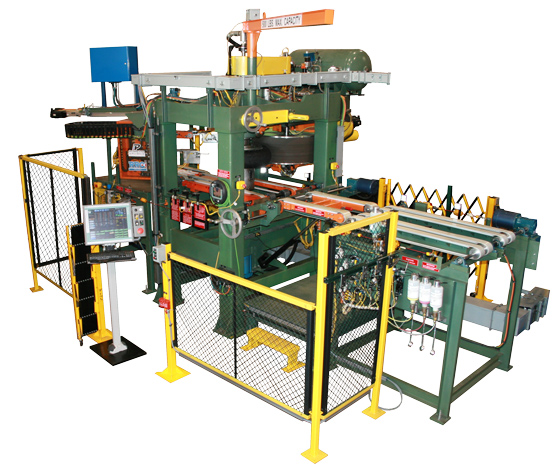

The new Poling Group MCX75 Tire Uniformity Tester builds on the success of the proven CX111 TU, applying the same smarter controls, faster through-put, and stronger frame to testing motorcycle tires.

Waveform Validation and Correction

A proprietary analysis of key machine parameters combining:

THE RESULT: The most accurate and consistent measurement possible along with industry leading speed and measurement repeatability sigma.

TDAQ - Tire Data Acquisition

Innovative and practical, TDAQ was specially developed by Poling Group to apply modern technology to test data acquisition.

Because a single TDAQ can process load cell and pressure transducer signals, two TDAQ cables (power and Ethernet) now efficiently replace the many wires leading back to the control panel of traditional tire test machines.

THE RESULT: Simplified wiring, combined with data acquisition located closer to the source, produce stronger and cleaner signals to bring about a substantial increase in resolution.

TTOC6 Controller

Our latest TTOC6 controller features new motion algorithms for tire sequencing, along with Waveform Validation and Correction software.

Our latest TTOC6 controller features new motion algorithms for tire sequencing, along with Waveform Validation and Correction software.

A testing machine with a TTOC6 and TDAQ data acquisition system can process tires SEVERAL seconds faster than any prior or currently competing machine.

THE RESULT: Now, your machines can satisfy production demands by testing, marking, and sorting more than 3 tires every minute while maintaining industry-required measurement repeatability.

Inflation Optimizaton software (TIO)

The CX111 was the first generation of tire test machines to use Poling Group’s new Inflation Optimizaton software (TIO) software, and the overwhelming success of the system has now been applied to our MCX75 motorcycle TU and X150 Truck/Bus TU. TIO monitors the machine's air regulation performance and adjusts the bead seat air release to more quickly stabilize tire inflation to the desired set point

The MCX75 also features a new servo-driven regulator that is less prone to failure due to contaminated air supplies.

THE RESULT: Poling Group’s improved air system delivers a faster load cycle, better measurement, and significantly reduced cycle time.

Automatic Adjustable Width Chuck (AAWC)

Updates to the AAWC stem increase cycle life and reduce failure:

Updates to the AAWC stem increase cycle life and reduce failure:

Patented Main Spindle Assembly

Our patented "cartridge" design main spindle assembly, now a standard feature for all Poling Group TU Testers, makes it possible to completely replace a test machine spindle assembly in about 3 hours, greatly reducing changeover downtime.

Our patented "cartridge" design main spindle assembly, now a standard feature for all Poling Group TU Testers, makes it possible to completely replace a test machine spindle assembly in about 3 hours, greatly reducing changeover downtime.

With properly trained associates, you can rebuild the assembly in the plant workshop.

Or, take advantage of our spindle exchange program - replace your worn-out spindle with our factory rebuilt cartridge assembly, then return the old spindle to us. We'll only charge you for the necessary replacement parts and rebuild labor.

THE RESULT: Stronger spindle assembly is easier to maintain with our after-market service.

* Machine is CE Certified

Waveform Validation and Correction

A proprietary analysis of key machine parameters combining:

- Current Waveform data

- Key machine values

- Historical performance

THE RESULT: The most accurate and consistent measurement possible along with industry leading speed and measurement repeatability sigma.

TDAQ - Tire Data Acquisition

Innovative and practical, TDAQ was specially developed by Poling Group to apply modern technology to test data acquisition.

Because a single TDAQ can process load cell and pressure transducer signals, two TDAQ cables (power and Ethernet) now efficiently replace the many wires leading back to the control panel of traditional tire test machines.

THE RESULT: Simplified wiring, combined with data acquisition located closer to the source, produce stronger and cleaner signals to bring about a substantial increase in resolution.

TTOC6 Controller

Our latest TTOC6 controller features new motion algorithms for tire sequencing, along with Waveform Validation and Correction software.

Our latest TTOC6 controller features new motion algorithms for tire sequencing, along with Waveform Validation and Correction software.A testing machine with a TTOC6 and TDAQ data acquisition system can process tires SEVERAL seconds faster than any prior or currently competing machine.

THE RESULT: Now, your machines can satisfy production demands by testing, marking, and sorting more than 3 tires every minute while maintaining industry-required measurement repeatability.

Inflation Optimizaton software (TIO)

The CX111 was the first generation of tire test machines to use Poling Group’s new Inflation Optimizaton software (TIO) software, and the overwhelming success of the system has now been applied to our MCX75 motorcycle TU and X150 Truck/Bus TU. TIO monitors the machine's air regulation performance and adjusts the bead seat air release to more quickly stabilize tire inflation to the desired set point

The MCX75 also features a new servo-driven regulator that is less prone to failure due to contaminated air supplies.

THE RESULT: Poling Group’s improved air system delivers a faster load cycle, better measurement, and significantly reduced cycle time.

Automatic Adjustable Width Chuck (AAWC)

Updates to the AAWC stem increase cycle life and reduce failure:

Updates to the AAWC stem increase cycle life and reduce failure:

- A deeper undercut diameter along the nose cone traps debris with less chance of scoring and galling

- We doubled the number of grease grooves and enlarged the grease feed holes

Patented Main Spindle Assembly

Our patented "cartridge" design main spindle assembly, now a standard feature for all Poling Group TU Testers, makes it possible to completely replace a test machine spindle assembly in about 3 hours, greatly reducing changeover downtime.

Our patented "cartridge" design main spindle assembly, now a standard feature for all Poling Group TU Testers, makes it possible to completely replace a test machine spindle assembly in about 3 hours, greatly reducing changeover downtime.With properly trained associates, you can rebuild the assembly in the plant workshop.

Or, take advantage of our spindle exchange program - replace your worn-out spindle with our factory rebuilt cartridge assembly, then return the old spindle to us. We'll only charge you for the necessary replacement parts and rebuild labor.

THE RESULT: Stronger spindle assembly is easier to maintain with our after-market service.

* Machine is CE Certified

Standard Features

- TTOC6 Machine Controller

- TDAQ - Tire Data Acquisition

- Timing Belt Center Conveyor

- Anti-Mischuck System

- Quick Inflate System

- Variable Speed Spindle Motor

- Precision Spindles and Bearings

- Frictionless Loadwheel Carriage

- Loadwheel Carriage Servo Motor

- 15 HP, 34 GPM Hydraulics

- X-Frame Technology

Optional Equipment

- Data Reporting System (FFH)

- Entrance Bead Lube System / Barcode Reader

- Automatic Lubrication / Greasing System

- Auto-Adjustable Width Chuck

- Radial/Lateral Runout Assemblies

- TSAS - Tire Surface Analysis System

- Quick Rim Change System

- Multi-level Sorting Conveyors

- Precision Test Rims

- Auto-position Center Grinder

- Dual Stone Shoulder Grinders

- Full List of Options in Main Menu "TU Options/Upgrades"

Machine Specs

Outside Diameter

Min 22 in

Max 32 in

Max 32 in

558 mm

813 mm

813 mm

Rim Width

Min 3 in

Max 11 in

Max 11 in

Cross Section Width

Max 13.5 in

343 mm

Tire Loading

Max 4,000 lbs

1,780 daN