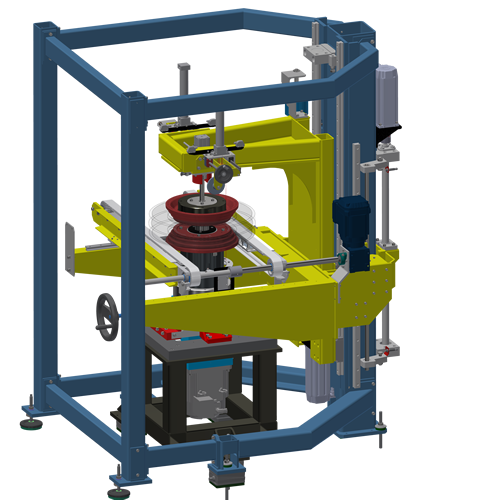

Coming Soon - The completely redesigned Poling Group DB111 Dynamic Tire Balance Tester.

The Poling Group Dynamic Balance Testing Machine has the capacity to balance test all tires processed by the CX111 Tire Uniformity Machine.

Since early 2022, the Poling Group has been completely redesigning the DB111 to create a superior balance tester with a focus on ease-of-maintenance, while having sound industrial-strength framework and only the latest components. Our flexible design provides the ability to measure dynamic imbalance on any range of tires also measured by a Poling Group CX111, or most other competitive TU machines.

Place the DB111 behind a CX111 machine to provide a single modular solution for Tire Testing, Grading, Marking, and Sorting for uniformity, geometry, and balance within a fully automated line.

* Machine is CE Certified

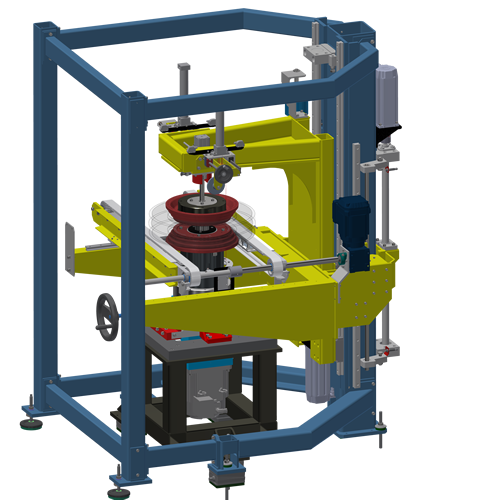

The Poling Group Dynamic Balance Testing Machine has the capacity to balance test all tires processed by the CX111 Tire Uniformity Machine.

Since early 2022, the Poling Group has been completely redesigning the DB111 to create a superior balance tester with a focus on ease-of-maintenance, while having sound industrial-strength framework and only the latest components. Our flexible design provides the ability to measure dynamic imbalance on any range of tires also measured by a Poling Group CX111, or most other competitive TU machines.

Place the DB111 behind a CX111 machine to provide a single modular solution for Tire Testing, Grading, Marking, and Sorting for uniformity, geometry, and balance within a fully automated line.

* Machine is CE Certified

Machine Specs

Outside Diameter

Min 22 in

Max 42 in

Max 42 in

558 mm

1067 mm

1067 mm

Bead Diameter

Min 14 in

Max 30 in

Max 30 in

356 mm

762 mm

762 mm

Rim Width

Min 3 in

Max 17.5 in

Max 17.5 in

Cross Section Width

Max 18.5 in

470 mm

Tread Width

Max 17.5 in

445 mm

Inflation Pressure

Max 85 psi

586 kPa

Tire Weight

Max 150 lb

68 kg

Spindle Speed

Max 120 RPM

*Optional 400 RPM

Rolling Radius

Min 10 in

254 mm

Shipping Weight

Approx 26,000 lbs

11,793 kg