Waveform Validation & Correction provides the most accurate and consistent measurement possible, with industry-leading speed and measurement repeatability sigma.

Read More About WVC

Machine Effect Characterization and Compensation is a patented concept for characterization of mechanical deficiencies and then compensation to mitigate the effect they have on the measurements.Read More About MECC

Simplified wiring, combined with data acquisition located closer to the source, produce stronger and cleaner signals to bring about a substantial increase in resolution.

Read More About TDAQ

- In addition to WVC and MECC software, the TTOC6 is equipped with Inflation Optimizaton (TIO) software that monitors the machine's air regulation performance statistics to quickly stabilize tire inflation to the desired set point.

- Integrated with our Tire Data Acquisition (TDAQ) product to substantially increase measurement resolution and improve noise immunity.

- Tire motion algorithms, along with WVC and TDAQ, allow a testing machine to test, mark, and sort more than 3 tires every minute, while maintaining industry-required measurement repeatability.

- Fewer electronic components, less points of failure, better reliability

- Online help with video for tooling changes

- Web-based message logs, servo setups and machine configuration

- "Instant Message" support at machine any time, all the time

- Variety of customizable architectural implementations

- Choose your PLC (Allen-Bradley/Rockwell, Siemens, etc.)

- Distributed or rack I/O

- Same full-function TTOC6 on new CX111 or Tier 1 Upgrade

- Modular design for scalability enables phased approach to tire testing improvements

- Compact flash drive allows standalone operation and no data loss if plant network fails

- Built-in and optional data acquisition and integration help you achieve shop floor and product traceability requirements

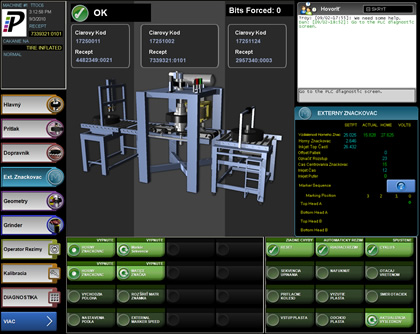

Diagnostics

DiagnosticsExtensive Diagnostics allow maintenance to control various PLC bits.

Customize a "favorites" screen, mixing analog and PLC I/O to display status for any machine function. The search function also makes it easy to find I/O of interest.

The data window contains current settings and actual values related to a specific area of control.

Customized Online Help

Customized Online HelpWe customize our help to match our customized test equipment. It includes photos and video to explain operational procedures and troubleshooting methods.

Users can select topics for general help, while calibration help appears automatically to guide users through these specialized tasks.

For help with responding to the current machine problem, just touch the alarm message in the status window.

Machine Visualization and Remote, Real-time Support

Machine Visualization and Remote, Real-time SupportThe machine visualization screen displays status. The thumbnail version of the screen includes cycle status indicators, while the full size version includes tracking data and fault details. This information is also instantly available for plant supervisors and engineers -- from their desktop computer!

Real-time support is only a touch away in the Chat Panel. The Chat Panel blinks to alert machine personnel to incoming messages. Once expanded, this instant messaging application allows direct communication with Poling Group engineers to solve problems - without waiting for support to arrive on-site.